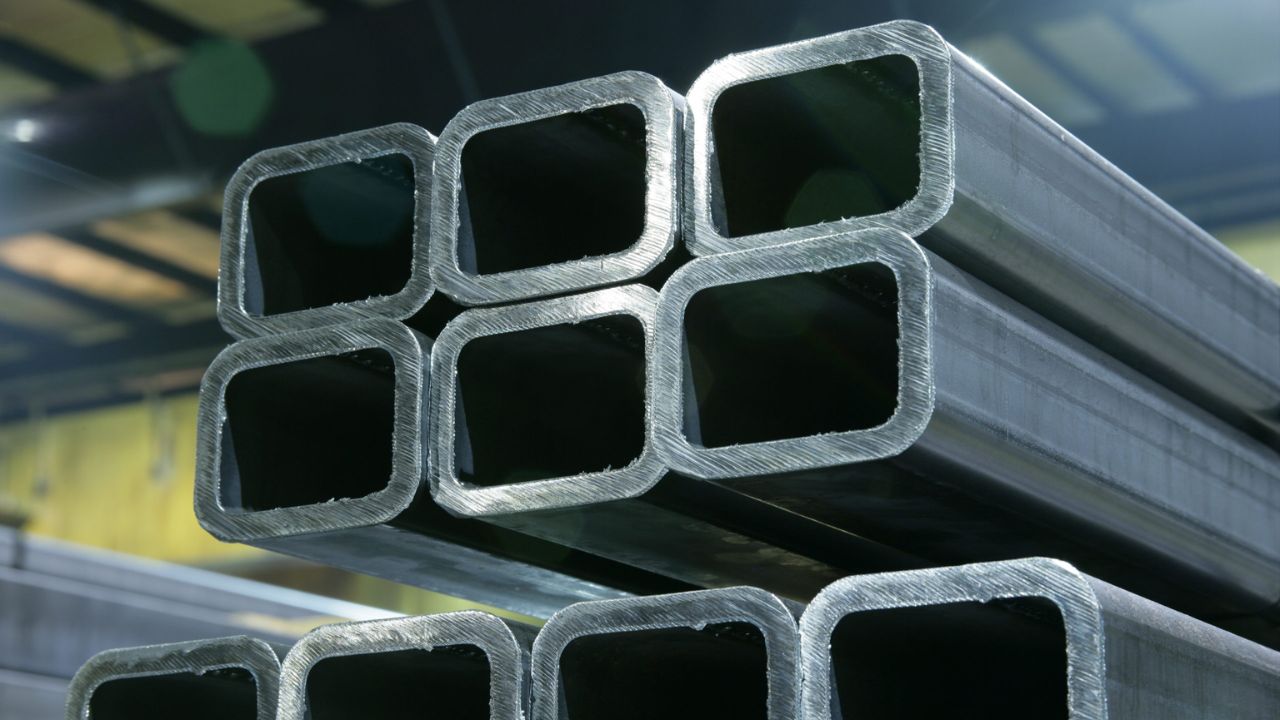

Hollow Structural Sections (HSS) are critical in the current construction, production and infrastructure works. The HSS tubes are powerful, versatile and effective and find application in buildings, bridges, machinery and other structures. The type of HSS tube size and material are important to ensure performance, safety and cost effectiveness. This article offers a detailed summary of the HSS Pipe-HSS Tube Size, specifications, and choice of materials used in HSS tubes to guide engineers, contractors and buyers to make sound decisions.

HSS Tube Sizes

HSS tube sizes are the geometric values that identify the outer and inner appearances of a hollow structural section. These dimensions are the outer, the wall thickness and the length of the tube. The outer size, commonly the outer diameter (OD), defines the overall size of the tube and its ability to fit within structural design concerns. The weight, strength and resistance to interior or exterior pressure of the tube are influenced by the thickness of the wall (t). The inner diameter (ID) is determined using the outer diameter and wall thickness, and it affects the flow capacity when an HSS tube is piping.

HSS tubes are produced in any shape, like circular, square, and rectangular sections. CHS are typically employed where equal load distribution and torsional resistance are needed. SHS, being a clean and equal-sided section, is preferred in architectural and aesthetic structures.

Material Selection

It is equally important to select the right material to use on HSS tubes as it is to select the right size. Carbon steel and stainless steel are the two most widely used types of materials. Carbon steel HSS tubes are strong, easy to weld and cost-effective, which makes them suited to all general construction and structural works. They may also find applications in buildings, bridges and machinery structures where a high strength/weight ratio is needed.

HSS tubes made of stainless steel, on the other hand, have better corrosion resistance and look better. They find extensive applications in architectural work, food processing plants, and places where moisture or chemicals are present. Stainless steel is more costly than carbon steel, but due to its long service life and low maintenance demands, it is a worthwhile investment in high-end and corrosive environments.

The grade of material is also a determining factor in performance. Harder steels have higher load-bearing capacity and could be applied to very stringent working conditions. Engineers must balance cost, weight, strength and corrosion resistance to determine the material that best fits their purpose.

Key Considerations in HSS Tube Selection

The choice of HSS tube sizes and materials depends on several factors. The load requirements dictate the thickness of the wall and the diameter of the wall required to be of a sufficient thickness to support the structure. In the case of fluid transportation systems, the level of pressure and the flow rate directly influence the material strength and internal diameter of the tube. In construction and bridge work, it is necessary to achieve stability and rigidity, such that the geometric design and section modulus must be carefully evaluated.

The other consideration is that of cost efficiency, as a larger diameter and a thicker wall will use more material and increase the expense of manufacturing items. Time, environmental factors, including temperature changes, exposure to corrosion, and mechanical stress, also affect material performance. After consulting the old manufacturers like Tianjin United Steel Piping (TUSPIPE), all the technical parameters and safety standards would be fulfilled to make it long-lasting.

The Future of HSS Tube Design

HSS tubes are rapidly evolving with improvements in the technology and materials science of manufacturing. Innovations in modern times also involve light alloys, better surface finishes and precision welding methods that save on volume production and costs. Smart controls and computer modeling can now enable engineers to monitor tube performance in real-time, enhancing safety and efficiency even more.

The use of HSS tubes in infrastructure development in the world will continue to grow as industries need heavier, more sustainable, and lighter materials. Learning the concept of the HSS tube sizing and the material selection, engineers and buyers can attain the maximum outcome of the strength, cost and duration of each work.

Conclusion

Proper choice of the size and material of HSS tubes is an essential stage in any construction or industrial undertaking. The individual dimensions and types of materials add capabilities to the performance, stability and durability of the tube. Through years of experience in the production of steel pipes, companies such as TUSPIPE offer quality and qualitative HSS tubes that satisfy international and project-related standards. With the emerging technological advancements, ongoing HSS tube production enhancement will facilitate the building of safer, stronger, and more efficient structures across the world.